tennant t300 parts manual

The Tennant T300 Parts Manual is essential for maintaining and servicing your floor scrubber. It provides detailed diagrams‚ part numbers‚ and instructions for repairs. Use genuine parts for safety and efficiency.

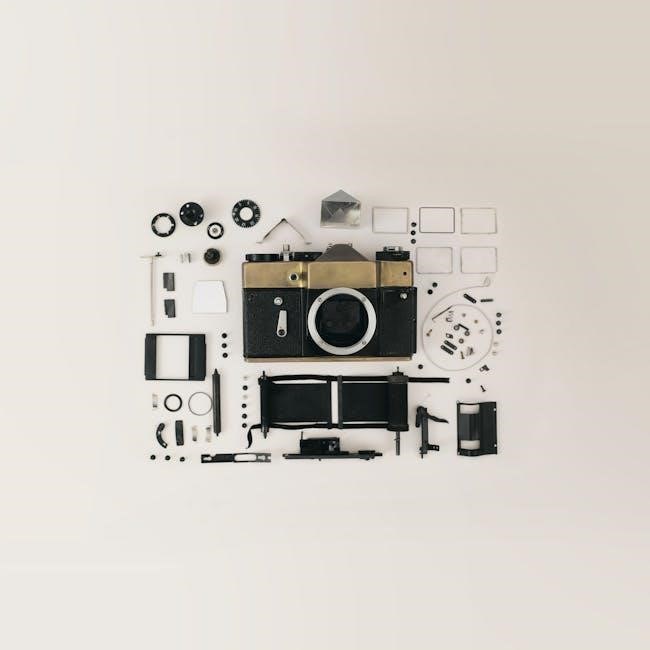

1.1 Overview of the Tennant T300 Floor Scrubber

The Tennant T300 is a high-performance automatic floor scrubber designed for commercial use. It is ideal for cleaning hard indoor surfaces in environments like hotels‚ schools‚ hospitals‚ and factories. Built for durability and efficiency‚ the T300 features a robust design that ensures consistent cleaning results. Its compact size and maneuverability make it suitable for diverse spaces‚ while its operator-friendly controls simplify daily operations. The machine is equipped with advanced technologies to maximize productivity and minimize downtime. Regular maintenance‚ as outlined in the parts manual‚ is essential to uphold its performance and longevity. The T300 is a reliable choice for businesses requiring a dependable floor scrubber for heavy-duty cleaning tasks. Its design emphasizes ease of use‚ making it a preferred option for both small and large-scale commercial applications.

1.2 Importance of Using Genuine Tennant Parts

Using genuine Tennant parts for your T300 floor scrubber is crucial for maintaining its performance‚ safety‚ and longevity. Genuine parts are specifically designed and tested to ensure compatibility and optimal functionality. They meet rigorous quality standards‚ guaranteeing reliability and durability. Non-genuine parts may compromise the machine’s efficiency‚ potentially leading to mechanical issues or safety hazards. Additionally‚ using authentic Tennant parts preserves the warranty and ensures compliance with manufacturer guidelines. This helps maintain the overall value of your equipment and reduces the risk of costly repairs. Always prioritize genuine Tennant parts to uphold the integrity and performance of your T300 floor scrubber. This approach ensures seamless operation and extends the lifespan of your investment.

1.3 Key Features of the T300 Parts Manual

The T300 Parts Manual is a comprehensive resource designed to simplify maintenance and repairs. It features detailed diagrams and illustrations‚ making it easier to identify and locate parts. The manual includes a complete list of part numbers‚ descriptions‚ and compatibility information to ensure accuracy. Step-by-step instructions guide users through complex procedures‚ reducing confusion. Additionally‚ it covers model-specific details‚ ensuring relevance for your exact machine. The manual also includes a glossary of technical terms and troubleshooting tips‚ enhancing usability. Regular updates keep the information current‚ reflecting any design changes or improvements. Whether you’re a professional technician or a DIY maintainer‚ the T300 Parts Manual is an indispensable tool for keeping your equipment in optimal condition. Its clear organization and detailed content make it a valuable asset for anyone working with the Tennant T300.

Identifying Parts for the Tennant T300

Identifying parts involves using model and serial numbers‚ parts diagrams‚ and descriptions to ensure accuracy. This process helps in locating the correct components efficiently for maintenance or repairs.

2.1 Understanding the Model and Serial Number

Understanding the model and serial number is crucial for identifying the correct parts for your Tennant T300. The model number‚ such as T300 or T300e‚ indicates the specific variant of your machine. The serial number‚ typically an 8-digit code‚ provides unique identification for your unit. Both can be found on the data plate located on the machine. These identifiers ensure accurate part lookup in the manual or when ordering from Tennant or authorized dealers. Always refer to these numbers to avoid mismatches and ensure compatibility. Using the correct model and serial number guarantees that the parts you order will fit and function properly‚ maintaining your machine’s performance and safety. This step is essential for efficient maintenance and repairs.

2.2 How to Locate the Serial Number on the Machine

To locate the serial number on your Tennant T300‚ start by examining the machine’s exterior. The serial number is typically found on a data plate‚ which is a metal or plastic plate attached to the machine. This plate contains key information about your unit‚ including the model number and serial number. On the T300‚ the data plate is usually located on the rear or side of the machine‚ near the control panel or operator compartment. It may also be placed on the base or frame. Look for a series of numbers labeled as “S/N” or “Serial Number.” This number is essential for ordering parts and ensuring compatibility. Once found‚ record the serial number for future reference to avoid confusion during maintenance or repairs.

2.3 Using the Parts Diagram for Identification

The Tennant T300 Parts Manual includes detailed diagrams to help users identify components accurately. These diagrams are organized by machine sections‚ such as the brush motor‚ drive system‚ and hydraulic components. To use the diagrams effectively‚ start by locating the relevant section that corresponds to the part you need. Each diagram labels parts with numbers and descriptions‚ making it easier to pinpoint the exact item. Once identified‚ match the part number to the manual’s index or parts list. This ensures you order the correct replacement. Always cross-reference the part number with the serial number to confirm compatibility. Using the diagrams simplifies the identification process‚ reducing errors and saving time. This visual guide is a valuable tool for maintaining and repairing your Tennant T300 efficiently.

2.4 Commonly Replaced Parts and Their Functions

The Tennant T300 Parts Manual highlights commonly replaced parts‚ such as the brush motor‚ drive system components‚ and hydraulic parts. These parts are crucial for the machine’s operation. The brush motor powers the cleaning brushes‚ ensuring effective scrubbing. Drive system components‚ like gears and belts‚ facilitate movement and traction. Hydraulic parts‚ such as pumps and valves‚ manage fluid flow for pressure cleaning. Regular wear and tear often necessitate replacing these parts. Understanding their functions helps in identifying when replacements are needed. Always refer to the manual for specific part numbers and compatibility. Replacing these components ensures optimal performance and extends the machine’s lifespan.

Maintenance and Servicing Guidelines

Regular maintenance ensures optimal performance. Includes cleaning‚ lubricating‚ and replacing wearable parts. Follow recommended schedules for filters and brushes. Proper care extends the machine’s lifespan and efficiency.

3.1 Recommended Maintenance Schedule

A well-structured maintenance schedule is crucial for the Tennant T300. Daily checks include inspecting brushes‚ filters‚ and solution tanks. Weekly‚ clean the recovery tank and check squeegee blades. Monthly‚ replace filters and lubricate moving parts. Every 500 hours‚ inspect and replace worn brushes and belts. Annually‚ service the hydraulic system and battery. Adhering to this schedule ensures optimal performance‚ reduces downtime‚ and extends equipment life. Always refer to the manual for specific intervals and procedures. Proper maintenance not only preserves the machine but also enhances cleaning efficiency and safety. Regular upkeep prevents major repairs and keeps the T300 in prime condition for consistent operation.

3.2 Step-by-Step Cleaning and Lubrication Procedures

Regular cleaning and lubrication are essential for the Tennant T300’s performance. Start by turning off the machine and allowing it to cool. Daily‚ remove debris from the brush and squeegee‚ and clean the recovery tank with mild detergent. Weekly‚ lubricate the caster wheels‚ brush bearings‚ and hinge pins using Tennant-approved lubricants. Monthly‚ inspect and clean the filters‚ and apply grease to the drive system. Every 500 hours‚ thoroughly clean the solution tank and check for wear on moving parts. Always follow the manual’s guidelines to avoid damage. Proper cleaning prevents dust buildup and corrosion‚ while lubrication ensures smooth operation and reduces wear. Consistent upkeep keeps the T300 running efficiently and extends its lifespan. Use only recommended cleaning agents and lubricants to maintain warranty compliance and performance.

3.3 Replacing Wearable Parts: Brushes and Filters

Replacing wearable parts like brushes and filters is crucial for maintaining the Tennant T300’s performance. Brushes should be replaced when they show visible wear‚ such as frayed bristles or uneven height. Filters‚ including the vacuum filter and solution filter‚ should be inspected monthly and replaced every 3-6 months or when visibly dirty. Use only genuine Tennant parts to ensure compatibility and longevity. To replace the brush‚ disconnect the power‚ remove the old brush‚ and secure the new one tightly. For filters‚ turn off the machine‚ locate the filter housing‚ and swap the old filter with the new one. Proper replacement prevents reduced cleaning efficiency and potential damage to the machine. Regularly updating these parts ensures optimal cleaning results and extends the life of your Tennant T300 floor scrubber.

3.4 Best Practices for Extending Equipment Life

To extend the life of your Tennant T300 floor scrubber‚ adhere to a consistent maintenance schedule and inspect wearable components regularly. Always store the machine in a dry‚ clean environment to prevent rust and electrical issues. Check brushes and filters frequently; replace them when worn or clogged to maintain optimal performance. Regularly clean the solution tank and recovery tank to avoid residue buildup. Lubricate moving parts as specified in the manual to reduce friction and wear. Ensure proper tightening of bolts and fasteners after repairs to prevent vibrations and damage. Use only genuine Tennant parts for replacements to guarantee compatibility and longevity. Train maintenance personnel on proper procedures to avoid misuse. By following these best practices‚ you can significantly extend the lifespan of your Tennant T300 and ensure it operates efficiently for years to come.

Troubleshooting Common Issues

This section guides users in diagnosing and resolving common mechanical and electrical issues with the Tennant T300. Refer to the manual for detailed solutions and diagnostic tools.

4.1 Identifying Common Faults and Symptoms

Identifying common faults in the Tennant T300 involves recognizing specific symptoms such as unusual noises‚ reduced cleaning performance‚ or machine shutdowns. Users should inspect for worn brushes‚ clogged filters‚ or hydraulic leaks. Monitoring the control panel for error codes can also help pinpoint issues. Regularly checking the brush motor and drive system for overheating or excessive wear is crucial. Electrical system problems may manifest as intermittent power or faulty sensors. By familiarizing themselves with these indicators‚ operators can address issues early‚ preventing downtime and extending the machine’s lifespan. Always consult the parts manual for detailed diagnostic guidance and solutions.

4.2 Diagnostic Tools and Techniques

Diagnosing issues with the Tennant T300 requires a systematic approach using the right tools and techniques. Start by consulting the parts manual for error codes and troubleshooting guides. Essential tools include a multimeter for electrical system checks‚ pressure gauges for hydraulic systems‚ and visual inspection for wear on brushes and filters. Utilize the machine’s control panel to identify fault codes‚ which can guide you to specific components. Regularly review maintenance logs to track recurring issues. For complex problems‚ diagnostic software provided by Tennant can offer deeper insights. Always ensure safety by disconnecting power before performing internal inspections. By combining these tools and methods‚ technicians can efficiently identify and resolve faults‚ minimizing downtime and ensuring optimal performance. Proper training and adherence to manufacturer guidelines are key to effective diagnostics.

4.3 Troubleshooting the Brush Motor and Drive System

Troubleshooting the brush motor and drive system of the Tennant T300 begins with identifying common symptoms like unusual noises‚ vibrations‚ or failure to operate. Check the power supply to ensure proper voltage and connections. Inspect the brush motor for blockages or debris accumulation‚ which can impede performance. Verify the drive belt tension and condition‚ as a loose or worn belt can cause inefficiency. Consult the parts manual for error codes related to the motor or drive system. Ensure all electrical connections are secure and free from corrosion. If issues persist‚ refer to diagnostic tools like multimeters to test motor windings or sensors. Always use genuine Tennant parts for replacements to maintain functionality. For complex problems‚ contact authorized service technicians. Regular maintenance‚ such as lubricating moving parts‚ can prevent premature wear. Proper troubleshooting ensures the T300 operates smoothly and extends its service life; Always follow safety guidelines when working with electrical and mechanical components.

4.4 Solving Hydraulic and Electrical System Problems

Addressing hydraulic and electrical issues in the Tennant T300 requires a systematic approach. Begin by checking hydraulic fluid levels and ensuring there are no leaks in hoses or connections. Inspect the hydraulic pump and motor for signs of wear or damage. For electrical problems‚ verify circuit breakers‚ fuses‚ and wiring for integrity. Use diagnostic tools to test electrical components like sensors and relays. Refer to the parts manual for specific error codes and troubleshooting steps. If a hydraulic component fails‚ replace it with a genuine Tennant part to maintain performance. Electrical issues may require professional assistance‚ especially if they involve complex circuitry. Always disconnect power before performing repairs to ensure safety. Regular maintenance‚ such as inspecting electrical connectors and hydraulic lines‚ can prevent unexpected downtime. Properly addressing these systems ensures optimal functionality and extends the life of the T300. Follow all safety precautions when handling hydraulic and electrical components.

Ordering and Acquiring Parts

Ordering parts for the Tennant T300 is streamlined through authorized dealers and online platforms. Use the parts manual to identify correct part numbers and ensure compatibility. Genuine Tennant parts guarantee quality and reliability.

5.1 How to Order Parts from Tennant Directly

Ordering parts directly from Tennant ensures authenticity and compatibility. Visit the Tennant website or contact their customer service to place your order. Provide your machine’s model and serial number for accurate part identification. Use the parts manual to locate the correct part numbers. Orders can be made online‚ by phone‚ or via fax. Payment options include credit cards or purchase orders. Shipping details and estimated delivery times are provided upon order confirmation. For bulk orders‚ inquire about discounts. Tennant’s dedicated support team is available to assist with any inquiries. Ensure all parts are genuine to maintain warranty and performance. Track your order through the Tennant portal for real-time updates. Regularly check for promotions or special offers. Tennant’s streamlined process ensures a hassle-free experience.

5.2 Using the Parts Manual to Find Correct Part Numbers

The Tennant T300 Parts Manual is a comprehensive resource for identifying and ordering the correct parts. Begin by referencing the manual’s detailed diagrams and part lists. Locate the specific section related to your machine’s model and serial number. Use the visual representations to pinpoint the exact part needed. Cross-reference the part number with the descriptions provided to ensure accuracy. Verify the compatibility of the part with your machine’s specifications. Note any additional accessories or tools required for installation. Double-check the part number before placing an order to avoid errors. The manual’s organized structure ensures quick identification‚ saving time and reducing the risk of ordering incorrect parts. Always refer to the latest version of the manual for the most up-to-date information.

5.3 Authorized Dealers and Third-Party Suppliers

Authorized Tennant dealers are the most reliable source for genuine parts‚ ensuring quality and compatibility with your T300 floor scrubber. They offer direct access to Tennant’s official inventory‚ reducing the risk of counterfeit or incompatible components. Third-party suppliers can also provide parts‚ often at competitive prices‚ but it’s essential to verify their credibility and the authenticity of the products. Always check for certifications or partnerships with Tennant to ensure reliability. When purchasing from third-party suppliers‚ review their return and warranty policies to avoid potential issues. For critical components‚ authorized dealers are recommended to maintain machine performance and warranty validity. Research suppliers thoroughly to balance cost and quality‚ ensuring your T300 operates efficiently and safely.

5.4 Tips for Ensuring Correct Part Fitment

Ensuring correct part fitment is crucial for the optimal performance and longevity of your Tennant T300. Always cross-reference part numbers with the official manual or supplier catalogs to confirm compatibility. Verify the part’s specifications‚ such as dimensions‚ material‚ and function‚ match your machine’s requirements. Inspect the packaging for any signs of damage or tampering before installation. When installing‚ follow the manufacturer’s instructions precisely to avoid improper fitment‚ which can lead to machine malfunction or safety hazards. If unsure‚ consult a certified technician or contact Tennant support for guidance. Proper fitment ensures safety‚ efficiency‚ and extends the life of your equipment. Double-checking these details saves time and prevents potential operational issues down the line.

Safety and Compliance

Adhere to safety guidelines when handling parts. Wear protective gear and follow manufacturer instructions. Ensure compliance with all regulations and dispose of used parts responsibly. Proper training is essential.

6.1 Safety Precautions When Handling Parts

Always wear appropriate personal protective equipment (PPE)‚ such as gloves and safety glasses‚ when handling parts. Ensure the machine is powered off and grounded before starting any maintenance. Avoid touching sharp edges or electrical components to prevent injuries. Keep loose clothing and long hair tied back to avoid entanglement with moving parts. Properly secure the machine to prevent accidental start-ups. Dispose of used parts responsibly‚ following environmental guidelines. Never reuse damaged or worn-out parts‚ as they can lead to machine failure. Refer to the Tennant T300 manual for specific safety instructions tailored to your model. Training personnel in proper handling procedures is crucial for maintaining a safe working environment. Always prioritize safety to minimize risks and ensure efficient repairs.

6.2 Compliance with Manufacturer Guidelines

Adhering to Tennant’s guidelines ensures optimal performance and safety. Always use genuine or equivalent parts specified in the manual to maintain warranty validity and prevent machine damage. Follow the recommended maintenance schedules and procedures outlined in the T300 manual to ensure compliance. Using unauthorized parts or deviating from guidelines can lead to safety hazards and void warranties. Familiarize yourself with local regulations and environmental standards when disposing of used parts. Proper documentation and record-keeping of maintenance activities are essential for compliance tracking. Training personnel according to Tennant’s recommendations guarantees adherence to safety and operational standards. Compliance not only extends equipment life but also ensures operational efficiency and reliability. Always refer to the T300 parts manual for precise instructions tailored to your model and needs.

6.3 Proper Disposal of Used Parts

Proper disposal of used parts from the Tennant T300 is crucial for environmental protection and compliance with regulations. Always follow local‚ state‚ and federal guidelines for hazardous waste disposal. Recycle materials like metals and plastics whenever possible. Hazardous materials‚ such as batteries or chemicals‚ must be handled separately and disposed of according to specific regulations. Check with local authorities or certified recycling centers for appropriate disposal methods. Ensure all fluids‚ like oil or hydraulic fluids‚ are drained and disposed of safely. Never dispose of parts in regular trash or dump them illegally. Refer to the Tennant T300 manual for specific disposal recommendations. Improper disposal can lead to environmental contamination and legal consequences. Always prioritize eco-friendly practices to minimize your environmental footprint while maintaining compliance with all applicable laws and regulations.

6.4 Training Requirements for Maintenance Personnel

Proper training is essential for maintenance personnel working with the Tennant T300 to ensure safety‚ efficiency‚ and compliance. Training should cover machinery operations‚ safety protocols‚ and diagnostic techniques. Personnel must understand the manual’s instructions‚ including part identification and replacement procedures. Training programs should emphasize hazard recognition‚ personal protective equipment use‚ and emergency response. Tennant recommends that all maintenance staff complete certified training courses or workshops. Regular updates and refresher sessions are crucial to stay informed about new technologies and procedures. Improperly trained individuals may inadvertently damage equipment or pose safety risks. Employers must ensure compliance with OSHA and other regulatory standards. Proper training not only enhances operational efficiency but also reduces downtime and extends the lifespan of the Tennant T300. Always prioritize thorough training to maintain a safe and productive work environment.

Leave a Reply

You must be logged in to post a comment.